NOTE: The DDEC VI engine control system monitors and controls the Aftertreatment Device for collected ash volume. In the even that maintenance is not performed or if maintenance is required due to unforeseen issues, the Amber Warning Lamp (AWL)/Check Engine light will light up to tell you that service is needed.

NOTE: Improper cleaning or care of the Diesel Particulate Filter or the Aftertreatment System can damage and/or destroy system.

Guidelines

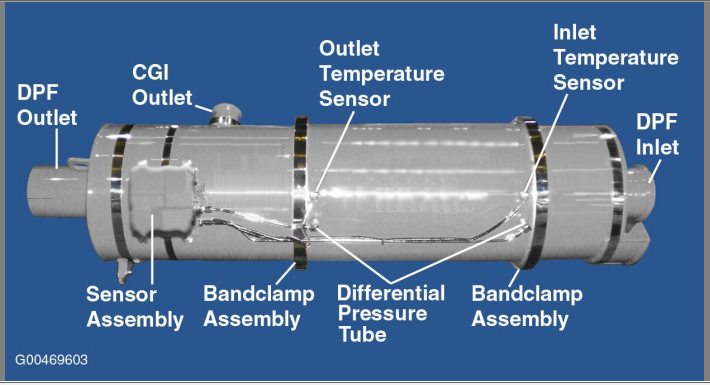

The 2007 Detroit engines are equipped with Aftertreatment Technology that will require maintenance (accumulated ash removal) for successful operation and performance over the life of the system. Several key parameters are critical to properly operating vehicles equipped with Aftertreatment Devices. Not following these guidelines will impact the system operation, may increase the frequency of maintenance above Detroit recommendations and result in additional repair incidents, and may impact warranty coverage of the component. The following are requirements for successful operation:

- Use Ultra Low Sulfur Diesel (ULSD) fuel with less than 15 PPM sulfur content.

- Follow the proper engine maintenance guidelines.

- Do not add used or new engine oils to your fuel (this promotes rapid ash creation).

- Do not use fuel additives containing chemicals such as lead, sulfur, or sulfated ash.

The following is recommended for successful operation. The use of genuine Detroit engine oil (part number 2351703), available at authorized Detroit service outlets. If not available, be sure the substitute meets the CJ-4 API index specifications, with less than 1.0% sulfated ash content. Using oils with greater than this level of ash content will result in a need to remove ash from the filter more frequently. Example: Using CI-4+ oil with 1.3% sulfated ash content will result in the need for cleaning 20%-30% sooner than suggested.

Detroit recommends using an authorized Detroit service outlet when completing or scheduling Diesel Particulate Filter (DPF) maintenance. Authorized service outlets are properly trained and equipped to inspect, evaluate, and handle the DPF. DPF is considered critical emission-related maintenance.

Authorized Detroit locations will be utilizing a Remanufactured DPF core exchange program. All plugged or ash loaded diesel particulate filters are returned to a Detroit remanufacturing facility for cleaning and qualification. This program ensures that the DPF is evaluated and cleaning using state of the art technology to provide the best assurance that your aftertreatment system if functioning properly following a maintenance event. All DPF center sections purchased through the parts distribution centers will be sold as remanufactured exchange units. These products are shipped in returnable containers that must be used for the safe return of your old core.

Detroit has evaluated many of types of cleaning equipment, including pressurized air cleaning devices for in shop utilization. These devices have not been able to provide consistent cleaning results above the specified efficiency. As a result, at this time Detroit does not recommend or endorse an equipment or process for cleaning other than the aforementioned Re-manufacture Exchange Program.

Service Record

NOTE: For warranty replacement of the Diesel Particulate Filter, Diesel Oxidation Catalyst or both, the Detroit warranty system will require input of this information.

It is recommended that customers or distributors maintain a proper record of the particulate filter servicing and cleaning. This record is an agent to warranty considerations. The record must include information such as:

- Date of cleaning or replacement

- Vehicle mileage at the time of cleaning or replacement

- Particulate filter part number and serial number